Control Tension by Controlling Brake Current

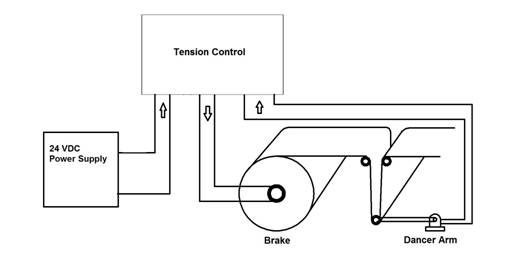

In a magnetic particle brake or clutch, torque is proportional to coil current. If coil current can be held constant, tension can be maintained in applications such as unwind stands, wire feed, and paper or film converting.

Ideal tension controls maintain coil current at a desired set point, and compensate for changes in the brake coil’s resistance (caused by heating) and input supply voltage.

In some applications closed-loop control is desired. A sensor provides a feedback signal proportional to tension. A dancer arm is typical of tension sensors.

In other applications it may be appropriate to allow the operator to manually set tension. Open-loop control can also be established using a roll diameter sensor.

In either case, the goal is to maintain constant coil current in the magnetic particle brake or clutch. An example of one of our constant current (or torque) tension controls is Regent Controls’ 8129. Typical loads include magnetic particle and hysteresis brakes and clutches. Benefits include:

- Accepts 0-10 VDC or 4-20 mA control signals

- Independent adjustments for Gain and Offset

- Use in closed-loop or open-loop tension control systems

- Compact size, snaps onto DIN rail

- Maintains constant load current

- Can be used in open or closed loop tensioning systems

Of note, magnetic particle brakes for tension control have a number of advantages over other types of brakes, including low consumption of power, making them a cost effective solution for many applications. Magnetic particle brakes for tension control also do not produce emissions or pollutants, making them a more environmentally friendly options than some other types of brakes.

Our experts are ready to help you select the right magnetic particle brakes for tension control for your application. For more information or to speak with a member of our team, contact us today. As a leading supplier of brake and clutch control power supplies, we have the expertise and custom capabilities required to help you meet your needs.